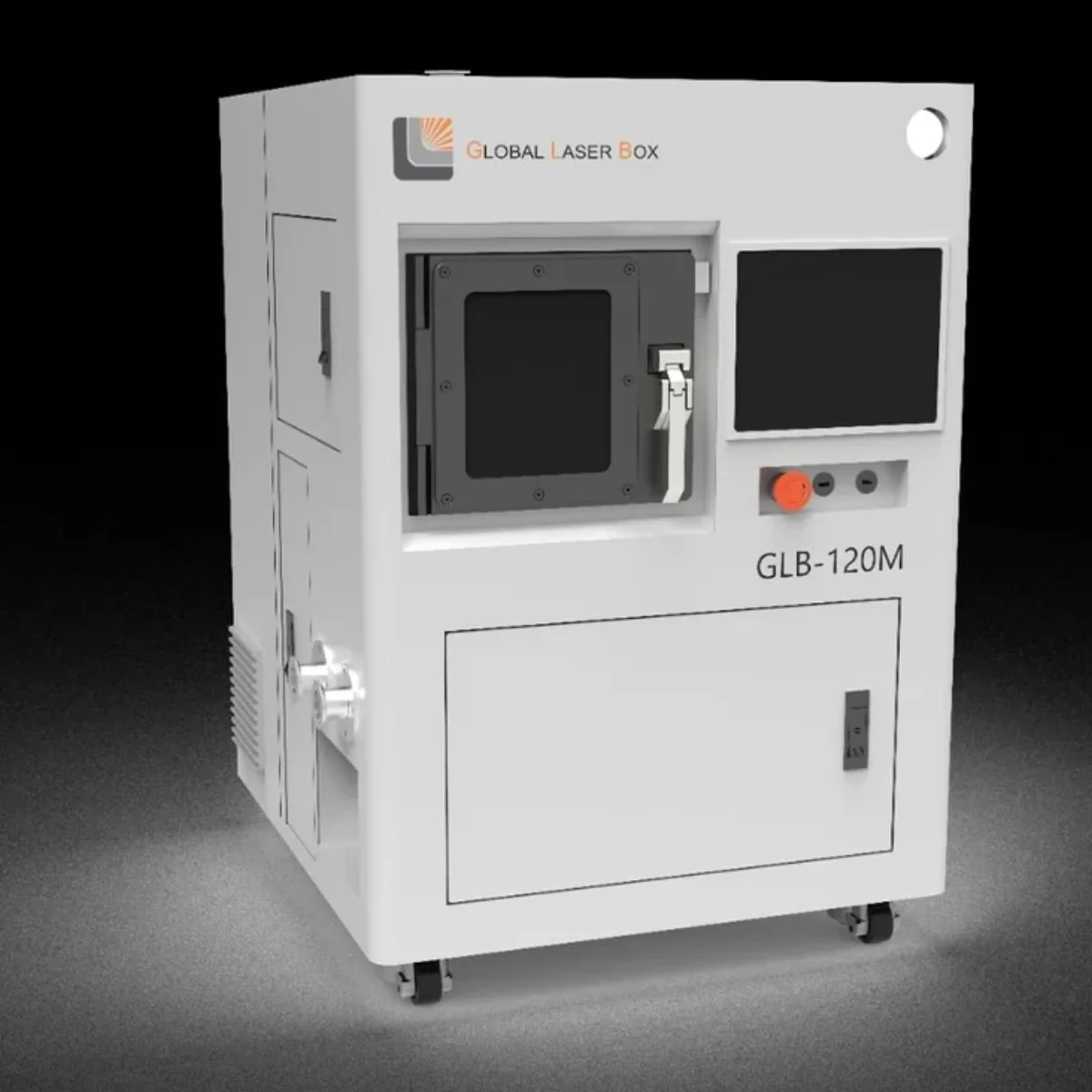

The GLB-120M Metal 3D Printer is engineered for high-precision additive manufacturing, delivering exceptional accuracy and strength for dental, medical, and industrial metal components. Built with advanced laser technology and optimized powder-handling systems, it ensures consistent, reliable, and high-quality prints from start to finish.

Key Features

- High-Precision Laser System

Ensures superior accuracy and smooth surface quality for complex geometries and fine details. - Optimized Build Volume

Ideal for crowns, bridges, dental frameworks, and compact industrial components—maximizing productivity without compromising print quality. - Stable & Uniform Printing

Controlled atmosphere and precise powder distribution guarantee consistency across every layer. - Durable Metal Component Compatibility

Works seamlessly with Co-Cr, stainless steel, and other approved metal powders for strong, long-lasting prints. - Efficient Powder Recycling System

Minimizes waste and ensures cost-effective operation in labs and manufacturing environments. - User-Friendly Interface

Intuitive controls and automated calibration make operation smooth, even for new users.

Applications

- Dental crowns, bridges, copings & RPD frameworks

- Implant components & custom attachments

- Small industrial parts and prototypes

- High-strength custom metal structures

Benefits

- High accuracy and repeatability

- Reduced production time and improved workflow

- Consistent surface finish with minimal post-processing

- Cost-effective metal printing for labs and workshops

- Designed for long-term durability and low maintenance